NEWS

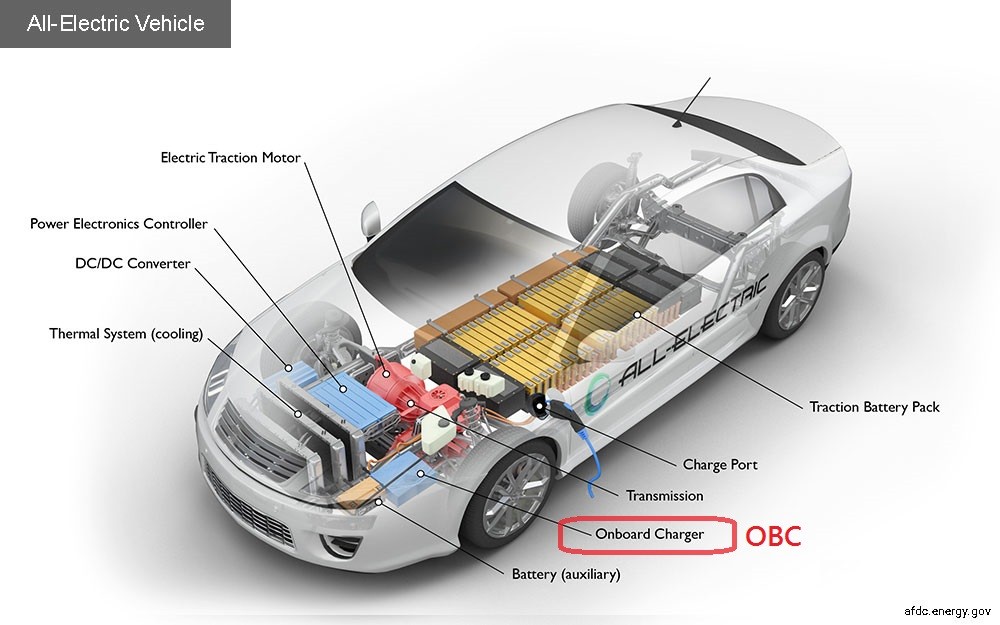

EMC testing for electric vehicle (EV) charging system included charging station, on-board charger, coupler, cordset and battery:

1. EV charging station (also called electric vehicle supply equipment (EVSE) or a charger that can be either AC or DC).

2. On-board charger (OBC) which is an integral part that building in almost every electric car.

3. EV charging coupler

4. EV charging cordset

5. EV battery

This article focus primarily on the on-board charger (OBC).

How does charging work?

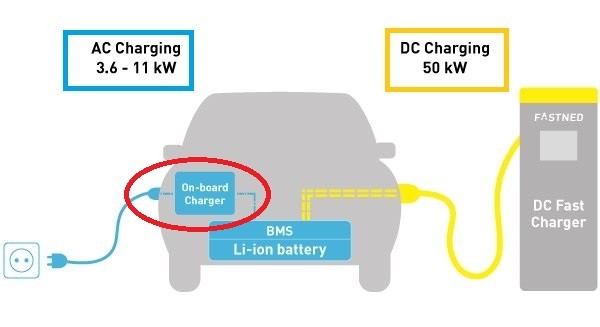

There are 2 basic types of charging, you can use either direct current (DC) or alternating current (AC).

If AC power is used, from the outlet or from the AC charging station, the current passes through the charging cable to the OBC, which converts the AC current to DC and sends it to the battery via the Battery Management System (BMS).

If DC power is used, then the OBC is bypassed and the current is sent via the BMS directly to the battery. Therefore, the OBC is not used during DC charging, but this charging style has higher demands on the BMS.

What is the role of an on-board charger (OBC)?

The primary role of an OBC is to manage the flow of electricity from the grid to the battery. It converts the AC input from the grid to a DC input which charges the battery. This is the most common charging method for EV today and most chargers use AC power.

The OBC allows you to control the current and voltage at which the battery needs to be charged (voltage or current control mode), thus taking care of the battery lifespan.

The charger offers either constant current or constant voltage charging, both of which are easy to operate. And each of them has its advantages and disadvantages. In the case of constant current charging, there is high efficiency and charging speed, but there is a risk that the battery will be overcharged at a later stage, and its lifespan reduced. In the case of constant voltage charging, there is a risk that too much current will flow into the battery from the beginning, which will heat the battery too much and shorten its lifespan again.

Thus, the charger ensures that it is initially charged with a constant current, thus maintaining speed and efficiency, and when the voltage at both ends of the battery reaches a certain amplitude, it changes to constant voltage charging. This system is called the charging strategy and it is the most important function of the on-board charger.

Relevant EMC standards?

Global: IEC 61851-21-1: 2017: Electric vehicle on-board charger EMC requirements for conductive connection to AC/DC supply. It applies only to OBC units either tested on the complete vehicle or tested on the charging system component level. It is also worth noting that IEC 61851-21-2: 2018 is available for off-board chargers. And the EMC standard for light electric vehicles (e.g. electric motor vehicles) that are in the drafting stage also points to IEC 61851-21-2.

U.S: UL 2202: Standard for Electric Vehicle (EV) Charging System Equipment.

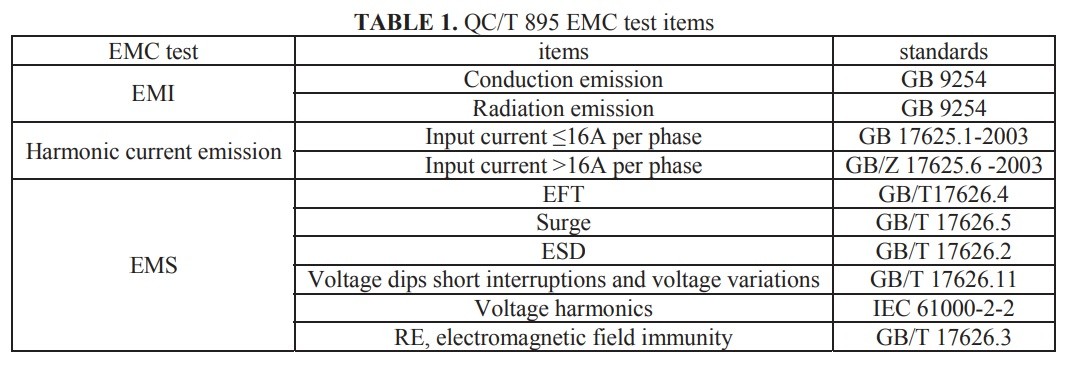

China: QC/T 895-2011: On-board Conductive Charger for Electric Vehicles.

As the connect link between power grid and electric vehicle, there has higher requirements for the EMC of OBC, in terms of safety, stability and power supply quality. For the OBC is to take power from grid, most of the test items are the same to civilian test items.

As automotive industry standards and access standards, the EMC is divided into three parts: EMI test, harmonic current emission test and EMS test (as shown in the following picture).

For the working condition, the current version of QC/T 895 standard regulates that the output end should connect resistive load, and should carry out full load output test. However, the regulation is difficult for the third-part laboratory that has already been constructed due to the limitations of circuit. Through the analysis of test results of dozens samples, the full load condition and half load or even light load conditions, the test results were almost the same. Therefore, R&D test can be carried out under light-load conditions.

Through the car charger EMC test and rectification project, the following methods has more obvious effect on improving EMC performance of OBC by testing and researching results of OBC:

- Rectify PC board level.

- Make a good grounding system.

- Plus magnetic ring or line filter.

- Shield it include input and output cables.

In order to pass the EMC test as soon as possible, most manufacturers adopt 3 and 4 the two kinds of high-effective rectification programs.

Data source: evexpert.eu; intertek; aip.scitation.org; hmr.araiindia.com; blog.greenenergyconsumers.org; afdc.energy.gov